Facing any of these challenges?

- You want to optimize in-plant logistics (intra-facility logistics) to increase productivity.

What can CM Plus do to build a better logistics plan?

A: CM Plus can

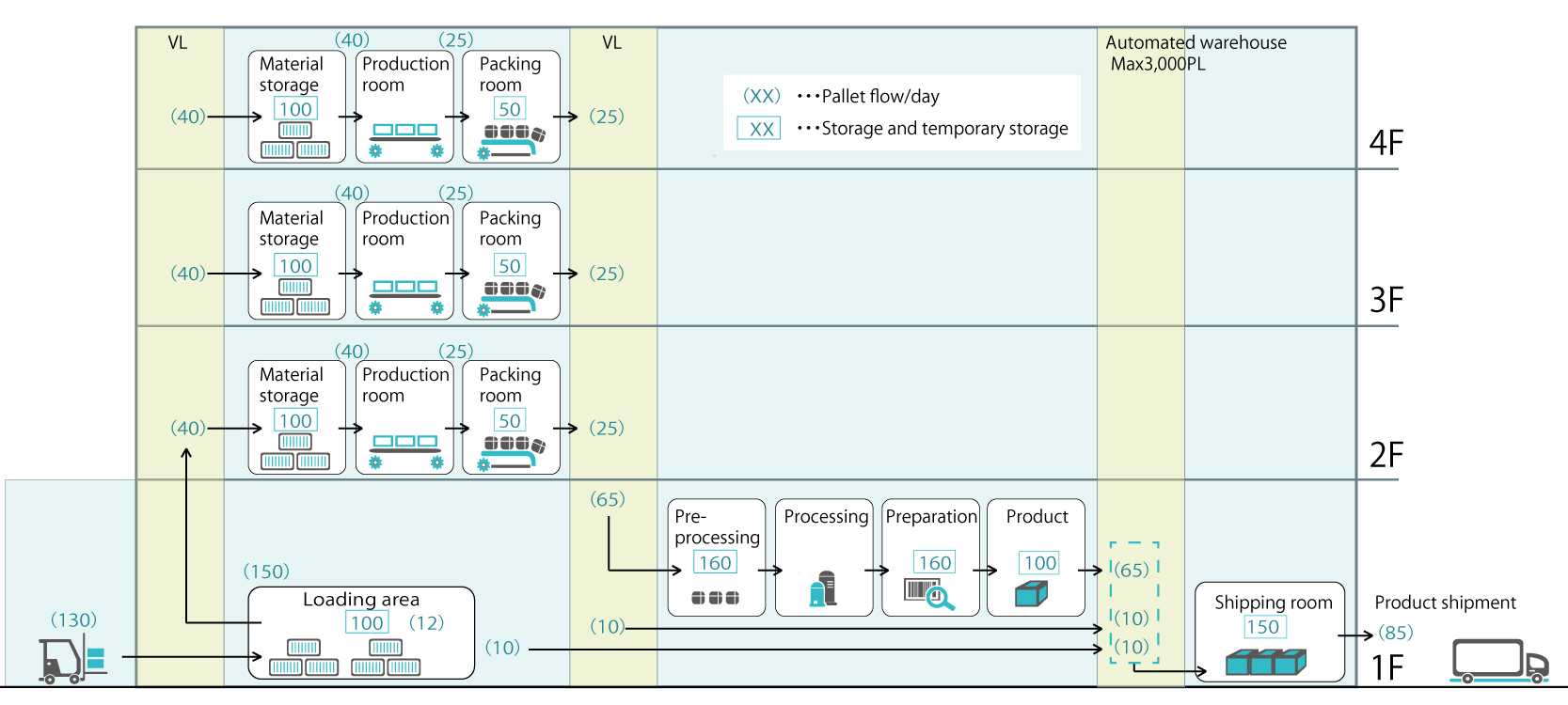

It is necessary to put in a warehouse, store, and ship “things” such as raw materials, intermediate materials, and finished products from the manufacturing process at the right time and place. CM Plus will organize the requirements on your behalf and collect the information necessary to create the optimal logistics plan. Within the factory, it is necessary to comprehensively look at the functions of each building, such as the office building, manufacturing building, and warehouse, analyze the flow of goods, logistics volume (people and goods), storage volume, etc., and create a practical and rational layout plan.

CM Plus document requirements, including production, logistics, and building functions, as a User’s Requirement Brief (URB) and create a site master plan. This makes it possible to “visualize” requirements throughout the entire factory planning and construction process, resulting in a factory with efficient logistics.

- What kind of transport equipment is best for automation and labor saving?

A: CM Plus can

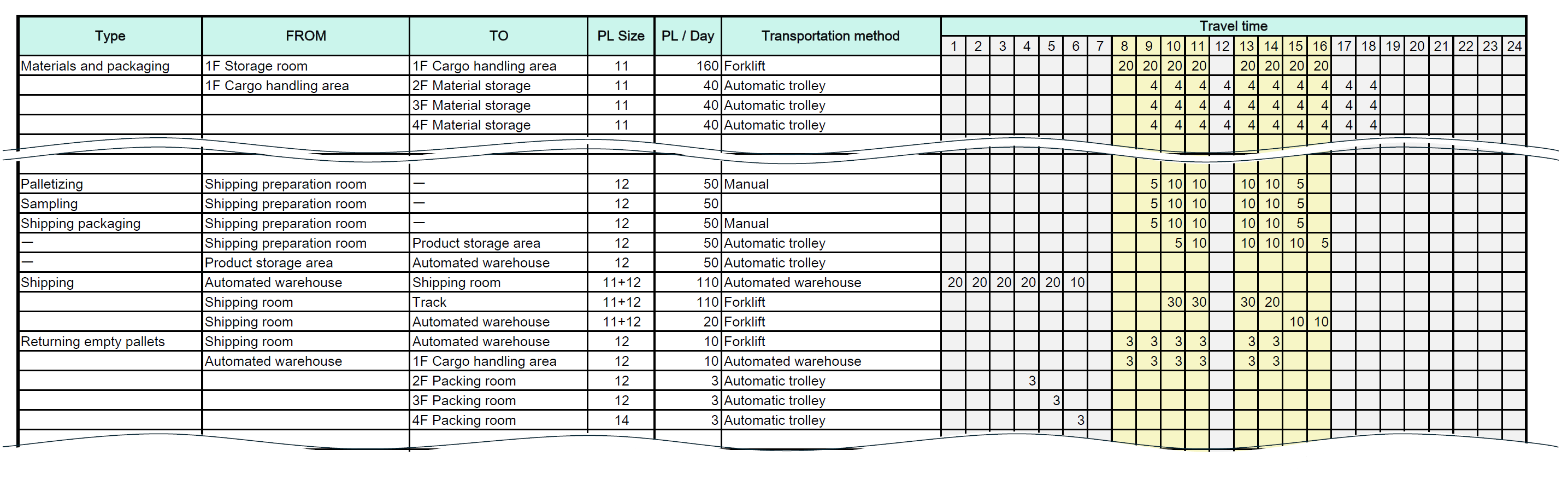

At the concept creation stage, CM Plus introduce the latest transport equipment and examples of its use to share an image with you. Simaltaneously, compile requirements for linking the logistics management system with ERP and MES.

- How should you arrange automated transport equipment such as AGVs within the premises?

A: CM Plus can

When introducing automated transport equipment, CM Plus advise you to consider the transport equipment and the building simultaneously.

- Type and number of transport devices

- Corridor width

- Warehouse capacity

- Method of delivery to and from production machines

- Method of managing transport data, etc.

CM Plus will comprehensively consider these factors and propose efficient logistics facilities and factory layouts to maximize functionality.

CM Plus’s strength

Comprehensive Review of Logistics, Production Equipment, and Buildings

As a construction management company with the engineering technology to design buildings, production equipment, and manufacturing control systems, CM Plus can create highly productive factories with logistics facilities based on line layouts, traffic flow, and equipment capacity.

Flow diagram

Logicstics time chart

Proven Project Management Skill

CM Plus provide design reviews and quality control utilizing our project management know-how cultivated through our extensive experience in factory construction, as well as document management using our in-house developed CORRESSA. CM Plus guide our customers’ construction projects to success by managing costs using a cost database we have accumulated over many years.

Compliant with Law, Regulation, and Guideline

For medical logistics, we design facilities that are in compliance with pharmaceutical GMP, GDP, and cosmetic GMP, as well as food safety, Halal, and other laws, regulations, and guidelines.

Capability for International Project

CM Plus has local offices in Japan, Singapore, Vietnam, and Indonesia and can provide local support in each language.

For the construction of large-scale logistics centers outside of Japan, we have partnered with Fukuda and Partners Co., Ltd.

Construction Project Flow of the Production Facilities

We will explain in detail the workflow for each project phase.

Project

A large-scale medical equipment manufacturing facility with the latest logistics system

- Consideration of automation of on-site logistics (including integration with existing buildings)

- Examination of floor plan, cross-sectional plan, in accordance with level of automation.

- Organizaing flow of people and goods, environmental standard, and closs-changing system

- Research on the latest information on logistics systems, and arrangement tours of the latest facility

- Evaluation of technical proposals and estimates from each logistics equipment manufacturer

- Support for direct ordering to equipment logistics manufacturers