Takasago International Corporation, a company with a long history founded in 1920, has always been at the forefront of fragrance technology, expanding its business from synthetic fragrances to fragrances and flavors. Moreover, the company has been expanding its business overseas from an early stage. Beginning with the establishment of offices in New York and Paris in 1960, Takasago has developed into a global fragrance company with bases in 28 countries and regions around the world.

Amid the global development of the Takasago Group, we asked about the new factory construction project in Indonesia that our company was involved in.

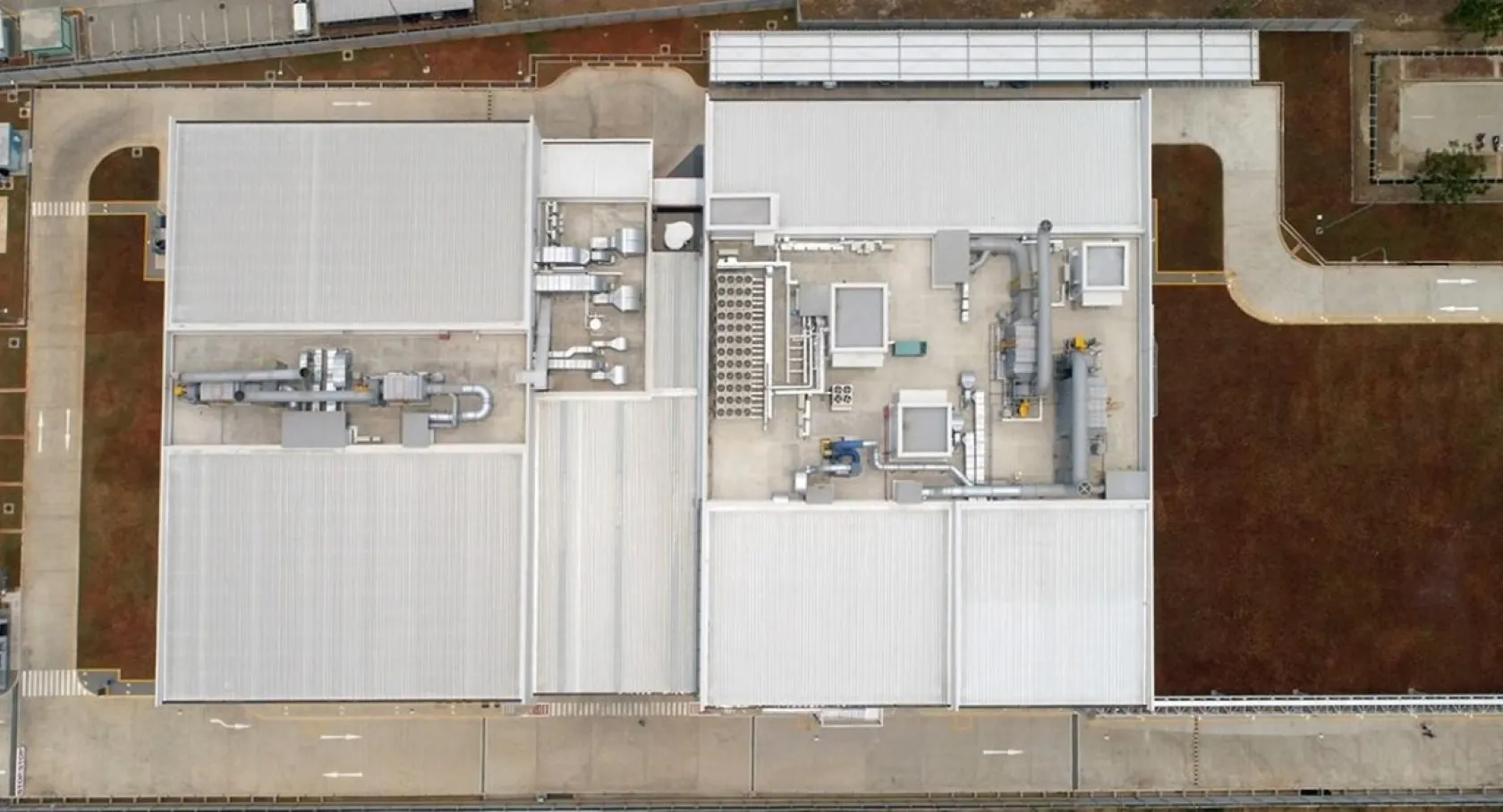

Factory Front View

Company Information

| Company Name | TAKASAGO INTERNATIONAL CORPORATION |

|---|---|

| Headquarters | Nissay Aroma Square 17F 5-37-1, Kamata, Ota-ku, Tokyo 144-8721, Japan Tel:81-3-5744-0511 Fax:81-3-5744-0512 |

| Founded | February 9, 1920 |

| Description of Business | Manufacturing and sales of flavors, fragrances, aroma ingredients, and fine chemicals. |

| Numbers of Countries with Subsidiaries | In 28 Countries and Regions |

| Numbers of Production SitesNumbers of Global Creation Centers | 13 |

| Numbers of Production Sites | 25 |

-

- Eisuke Shimokawa

- Corporate Headquarters, Global SAP Management Department

F&A Module Leader

(During the interview)

- During the project execution

- Manager

Administration and Key Projects

Takasago International (Singapore) Pte Ltd

-

- Naoki Saito

- Production Headquarters, Production Strategy Department, Production Planning Group

Manager

(During the interview)

- During the project execution

- Production Manager

Production Department

Takasago International (Singapore) Pte Ltd

Concept and Positioning of the Indonesia Project

- CM Plus

- First, could you tell us about the concept and positioning of the Indonesia project at your company?

Shimokawa

Shimokawa- Our company expanded to Singapore in 1975. The Singapore office functioned as the regional headquarters for the ASEAN region, including Indonesia, overseeing and controlling business activities in the area. However, we faced challenges in capturing business opportunities effectively in Indonesia, which has the largest market in ASEAN. Although it is a highly competitive market, our major issue compared to competitors was particularly in lead time. To address this, we decided to expand into Indonesia. Although our company had already entered the market, the discussion now was about establishing a manufacturing base.

This marks the first step in setting up our factory in Indonesia.

During the initial stages of planning the factory, we considered Indonesia as a satellite factory, as we already have a suitable regional headquarters in Singapore.

- CM Plus

- I now understand the positioning of the Indonesia factory. When you say “initially,” does that mean that your initial concept changed direction somewhere along the line, perhaps due to market changes?

Shimokawa

Shimokawa- There were no significant changes in the concept from the perspective of market changes.

- CM Plus

- Then, approximately speaking, the factory was realized as planned initially.

Shimokawa

Shimokawa- Yes. However, I think we initially anticipated simpler production processes. In the conceptual stage, we envisioned simpler processes than what are actually in operation now. As the project progressed, the processes became more complex, resembling those of the Singapore factory.

- CM Plus

- So, were there any modifications to the equipment after the factory was initially completed?

Saito

Saito-

No, there were no modifications. Although we had to produce from scratch using various raw materials in Indonesia, from the perspective of raw material procurement, the Indonesian factory had to operate reliably. In other words, the satellite factory needed to become independent rather than remaining under the Singapore headquarters. This advancement happened earlier than initially expected.

The only change from the initial concept was this aspect. The products we manufacture or our business operations did not change.

- CM Plus

- So, the scope of the production process expanded beyond the initial concept, and as a result, the factory’s positioning became more important earlier than anticipated.

Factory Concept

Factory Layout Diagram

Concept and Future Plan During Planning and Reality

Shimokawa

Shimokawa- I’m no longer directly involved with the Indonesia project, but from what I’ve heard, some plans that were initially intended to be implemented after increasing business volume have moved forward ahead of schedule. It seems there has been investment in the warehouse.

- CM Plus

- I see, this relates to the “construction concept and future plans” that I wanted to ask about. What were the construction concepts and future plans considering the production scale and the products you intended to create?

Shimokawa

Shimokawa- In terms of the construction concept, the idea from the Singapore president back then was to start small with minimal investment, creating a simple factory, and then grow big. The initial concept was to allow ample space for future expansion and produce low-cost, high-quality products. Compared to that initial concept, the amount of investment and the scale of the equipment and factory space have since been revised upwards.

- CM Plus

- Has the future space that was secured at the time of the project’s completion, where our company participated as a CM company, already been used?

Shimokawa

Shimokawa- As I mentioned earlier, part of it is being used for a warehouse. There was a considerable open space on the right side of the flavor building, but now there’s a building that wasn’t there at the time of completion.

- CM Plus

- You mentioned that an extension for the warehouse was implemented. Is the primary market that necessitated this within Indonesia? I believe there are both Japanese corporations and local corporations in Indonesia…

Shimokawa

Shimokawa- Yes, the market is primarily within Indonesia.

Design Concept and Safety in a Factory Meeting Global Standards

- CM Plus

- Regarding the design of the factory layout, the concept of separating flavors and fragrances was a fundamental concept from the beginning of the construction project. How do you see that aspect? For example, have there been any comments from Takasago’s customers or visitors to the factory, such as “It’s great that they’re clearly separated”?

Shimokawa

Shimokawa- Just around the time we started designing the Indonesian factory, there was a growing awareness within the entire Takasago Group about the design concept, and guidance from the headquarters to overseas factories became clearer. The design policy of clearly separating flavors and fragrances, ensuring space between them to prevent contamination, was implemented in each factory. This approach was clarified and led by the headquarters, reflecting in overseas projects as well. Furthermore, there has been a significant increase in the stringent requirements related to safety.

Saito

Saito- Takasago has factories all over the world, each rooted locally and continually improving to build various factories. While the advancements made at the local factories were beneficial, there was a period where slight discrepancies started to appear between the perspectives of the headquarters and the local factors. The clear initiative to adopt a global plant design concept was introduced around the time our Indonesian construction project began. Therefore, this Indonesian factory holds the position of being the first to embody the Takasago Group’s global concept.

- CM Plus

- I see. So, this is the first factory that follows a strict design concept and safety requirements aligned with the global concept.

About CM Plus Services

Reasons for Choosing CM Plus

- CM Plus

- Could you tell us the reasons for selecting CM Plus and share your thoughts?

Shimokawa

Shimokawa- For our Singapore factory, we constructed the building through the local subsidiary of a Japanese construction company and entrusted the production machinery to a local company. We used a project management company to oversee the whole process. For the factory in India, we almost exclusively used local companies, although the construction company was a local subsidiary of a Singaporean company. When it came to the Indonesian factory, there was internal discussion that it would be better to ask a reputable Japanese general contractor, and we were looking for a CM company to support competitive bidding along with basic planning and design. That was how we came to know and choose CM Plus.

- CM Plus

- How did you come to know about our company, CM Plus?

Shimokawa

Shimokawa- We were introduced to CM Plus by the facility company that helped us with the Singapore factory. We believe it was indeed a fortunate connection.

- CM Plus

- Our company, CM Plus, has been providing engineering design support and CM services since our founding, but we understand that our recognition is still low, and we know we must continue to strive to improve. In this context, it is a great honor for us to receive work through referrals from those we have previously worked with on projects.

Positive Aspects and Areas for Improvement Using CM Plus Services

- CM Plus

- Please share your impressions of the benefits and any areas for improvement from utilizing our services.

Shimokawa

Shimokawa- I was responsible for project management and cost control, and having CM Plus involved gave me a great sense of security. Although there was an expense involved in hiring a CM company, I believe it was worth it. For example, during the basic planning phase, the construction cost estimates provided by your company had very little deviation. Regarding the project timeline, while there were some minor discrepancies, these were due to reasons I will explain later, not because of any major deviation from what CM Plus was handling; thus, I felt reassured.

- CM Plus

- Thank you for your appraisal regarding schedule and cost management. During the basic design and bidding process, we created concept designs, prepared basic design documents, and bidding documents, and provided bidding support. Although the competition was limited to Japanese general contractors, we believe we successfully fostered a competitive environment. How would you evaluate this aspect?

Saito

Saito- That is the part we are most thankful for. In this project, there was no dedicated person in charge of the construction project. While handling our regular work, we also had to coordinate with equipment vendors for production facilities. We didn’t have the time to create bidding documents for the construction work, nor did we have professional engineering skills. In this regard, your support was invaluable.

Shimokawa

Shimokawa- Indeed, creating bidding documents was difficult for us. The cost estimates provided during the basic planning phase were accurate, which helped with cost management. Clear and well-prepared initial documents enabled us to land close to the original estimates without significant discrepancies.

- CM Plus

- Thank you. We are honored to hear that our services aligned well with Takasago’s needs for the Indonesian factory. Regarding the construction phase, our local staff visited the site weekly, and additionally, we conducted monthly site inspections from Japan. We determined that this frequency was appropriate based on our experience with Japanese general contractors.

Shimokawa

Shimokawa- The request from CM Plus for the construction company to provide monthly documented reports was something we wouldn’t have thought of. It was very helpful.

- CM Plus

- Some clients may prefer to minimize costs and leave the construction entirely to a Japanese general contractor, feeling they don’t need our services after the detailed design phase. We’re glad to hear that you valued our continued involvement even during the detailed design and construction phases.

Shimokawa

Shimokawa- Your professional perspective supplemented our gaps in communication. Having worked together from the initial basic planning phase, you understood our goals well, which was a significant advantage.

Saito

Saito- Additionally, your familiarity with Indonesia’s environment was crucial. We didn’t fully understand the regulations related to construction in Indonesia. There were many things we heard at the rumor level, but the exact facts were unclear. Your prior research was very helpful.

- CM Plus

- With regard to local information, we believe our local Indonesian subsidiary and staff, who understand the local context, were able to assist effectively.

Regarding Production Equipment

Adoption of Local Production Equipment Vendors

- CM Plus

- By the way, you procured production equipment from local companies. What percentage of the total cost was spent on procuring production equipment within Indonesia?

Shimokawa

Shimokawa- It exceeded 20%, but did not reach 50%. There were one or two expensive pieces of equipment, and including those would increase the percentage. This time, we ordered such equipment from outside Indonesia. We ordered simple items from Indonesia, but for items requiring more precision, we ordered from places like Singapore or Europe.

- CM Plus

- I see, you selected the suppliers best suited for each case.

Communication with Local Production Equipment Vendors

- CM Plus

- I assume it must have been challenging, but how was your experience dealing with local companies regarding coordination of quality and schedules?

Saito

Saito- The most challenging aspect of this project was dealing with production equipment. Initially, we assumed that the Indonesian plant would have a simple process similar to what we were doing at the Singapore plant. Therefore, we decided from the beginning that local procurement for production equipment would be sufficient, given our existing knowledge. However, when it came to choosing vendors, it was difficult. We approached three or four companies but lacked sufficient information to determine which one was good. In the end, we ordered tanks from a vendor in Surabaya, which is quite far from our factory. In hindsight, we struggled not with the quality of the tanks themselves but with what might be called the “quality of the work.”

- CM Plus

- You mean the way their work was conducted rather than the quality of their products.

Shimokawa

Shimokawa- Their response times were slow, and even when we tried to have direct meetings, it was difficult due to the distance. This pace of communication might be their standard. We proceeded without fully understanding this, which ultimately impacted the overall project schedule. This is something we need to learn from.

- CM Plus

- However, in terms of cost, wasn’t it cheaper?

Shimokawa

Shimokawa- Yes, in terms of cost, it was cheaper. We received offers from Japanese engineering companies, but they couldn’t compete with local companies on cost.

- CM Plus

- So, in a sense, cost and schedule were a trade-off. The schedule coordination was challenging, but you kept costs down and ultimately completed the project successfully?

Shimokawa

Shimokawa- Delays in production equipment extended the construction schedule, but thanks to the cooperation of the construction company, we were able to complete the project without incurring significant additional costs.

Customer Feedback on Post-Factory Operation Services

After Project Completion and Factory Operation

- CM Plus

- We recognize that we have not been able to maintain continuous contact and follow-up with our customers after the completion of a project. In this regard, we would appreciate any advice on how we should build a continuous relationship with Takasago International Corporation.

Saito

Saito- Since we do not build factories on a daily basis, it is difficult for us to regularly request similar services. However, we have received periodic contacts from CM Plus’s Singapore office, and this has given us a sense of security, knowing that we can consult with them whenever necessary.

- CM Plus

- Thank you very much.

In light of recent global developments, we have begun offering energy solutions services. This service involves investigating how energy savings and CO2 reductions can be achieved at the operating factory and providing information on this subject. Since those working on the manufacturing floor primarily focus on production, we believe that by continuously investigating and providing advice on energy solutions, we can identify opportunities to reduce the factory’s energy consumption and provide benefits to our customers. We believe that such considerations and measures will be increasingly necessary, especially overseas.

Saito

Saito- Thank you for introducing your services. This is a perspective that we have not been able to focus on much in our regular operations.

At Takasago Head Office

From central left: Mr. Saito and Mr. Shimokawa of Takasago International Corporation

Far left: Our company (CM Plus) Tsukada; Far right: Our company (CM Plus) Togashi

PT. Takasago International Indonesia Members

PT. Takasago International Indonesia Members

Although we could not speak with them directly this time, we are deeply grateful to Mr. Iswanto Juandy Tjeng, President of PT. Takasago International Indonesia.

At PT. Takasago International Indonesia Factory

From left: President Iswanto Juandy Tjeng; Our company (CM Plus) Lanny

Takasago International Corporation

PT. Takasago International Indonesia

Note: The information included in the interview article reflects the situation at the time of the interview.

Related Services

Related Contents

Engineering testimonials

-

Engineering World Recognized Highly Pharmacologically Active Manufacturing Facility

Engineering World Recognized Highly Pharmacologically Active Manufacturing Facility

~Breaking new ground beyond the “Wall of 0.05μg/m3 Chugai Pharma Manufacturing Co., Ltd. -

Engineering Japan's first containerized data center to support cloud computing services was built in Matsue City, Shimane Prefecture. Internet Initiative Japan Inc. (IIJ)

Engineering Japan's first containerized data center to support cloud computing services was built in Matsue City, Shimane Prefecture. Internet Initiative Japan Inc. (IIJ)

-

Engineering As a partner for the new location project because of its knowledge of the pharmaceutical industry, technical capabilities, and flexibility. From conceptual design to construction, we managed costs and schedules thoroughly. Iwata Label Co., Ltd. (currently IL Pharma Packaging Co., Ltd.)

Engineering As a partner for the new location project because of its knowledge of the pharmaceutical industry, technical capabilities, and flexibility. From conceptual design to construction, we managed costs and schedules thoroughly. Iwata Label Co., Ltd. (currently IL Pharma Packaging Co., Ltd.)