Table of Contents

What is DX (Digital Transformation)?

First, let us explain DX (Digital Transformation) from the example of the roadmap.

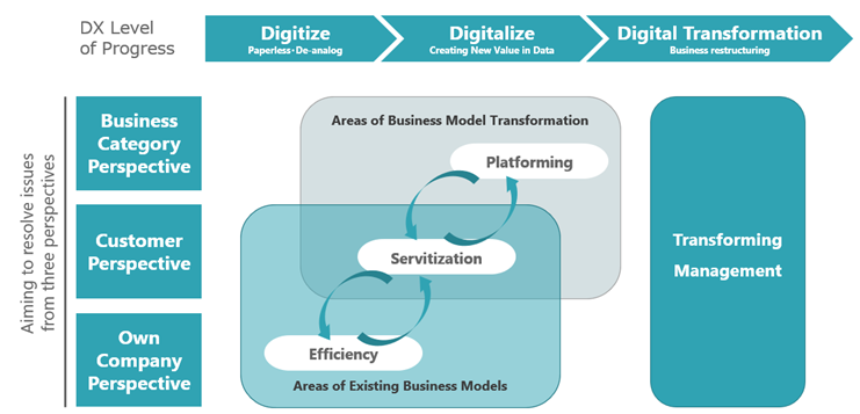

The progress levels of DX are shown in the upper part of the fig.1 as “Digitize,” “Digitalize,” and “Digital Transformation. While anticipating the digitalization of the industry, it is important to raise issues from the three perspectives shown in the left part of the Fig.1 and utilize digital technology to solve them.

The three perspectives are “business category perspective,” “customer perspective,” and “own company perspective,” and it is important to address issues from each perspective in the existing business model area and the business model transformation area. The ultimate goal of DX is to promote individual digitalization, which will lead to business and management restructuring.

Fig. 1: Roadmap for DX implementation

DX for digital data handling

Let us consider the case where the focus is on handling digital data as DX implementation.

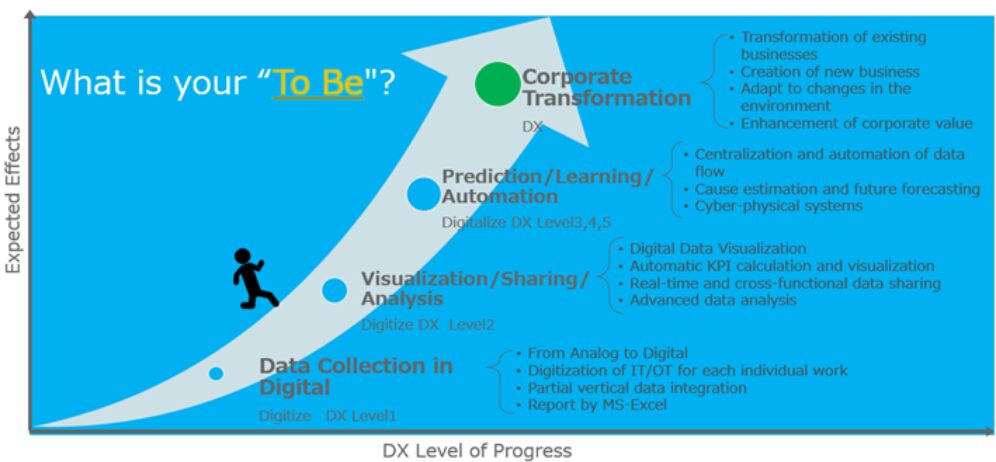

We believe that the ideal situation is to start from the first stage of digital data collection shown in the left part of the Fig.2 and move toward the upper right, through data visualization/sharing/analysis, to forecasting/learning/automation, leading to corporate transformation. What level to aim for and where to set the goal as “To Be” are also important factors.

Fig.2 DX on Digital Data (DX Progress Level – Expected Effectiveness)

KPI:Key Performance Indicator

IT/OT:Information technology / Operational technology

Organizing the control system hierarchy

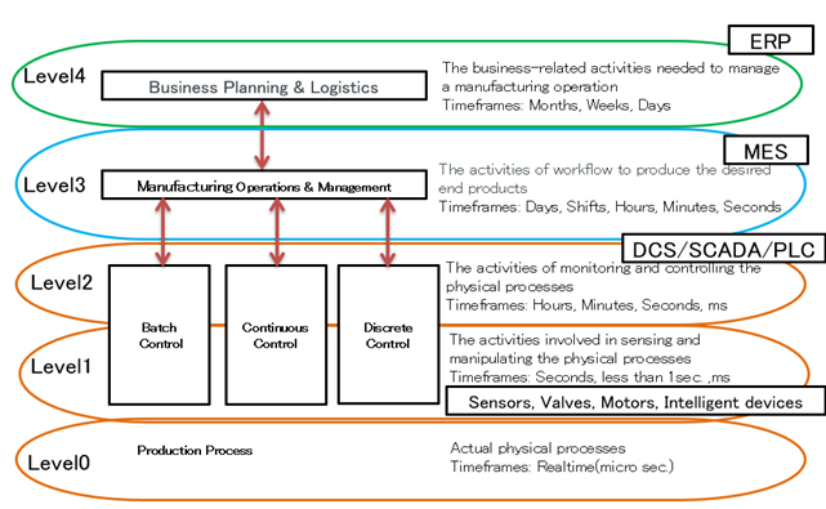

The hierarchy of control systems, including production management, in a factory is generally structured as shown in Fig.3.

This is based on the ISA95 (International Society of Automation: an international standardization organization for automated equipment) reference model of a factory, which defines the interface between the management system and the boundary of the manufacturing system.

This Fig.3 shows the data cycle and processing details handled at each level.

Each levels are defined as follows: from the field at Level 0, Level 1 field devices such as sensors, valves, motors, and instruments, Level 2 various control devices, Level 3 MES (Manufacturing Execution System), and Level 4 ERP (Enterprise Resource Planning).

It is easy to start considering how to solve issues at each level, but with the development of ITOT, it is becoming possible to process data at higher levels.

Fig.3 Control Level Hierarchy defined by ISA

ERP:Enterprise Resources Planning

MES:Manufactureing Execution System

DCS:Distributed Control System

SCADA:Supervisory Control and Data Acquisition

PLC:Programable Logic Controller

If you need help with DX for your pharmaceutical factory, please feel free to contact us.